|

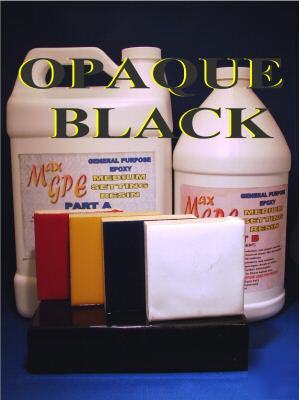

BLACK EPOXY RESIN SUITABLE FOR FIBERGLASS LAMINATING AND IMPRENATING OTHER AVAILABLE COLORS Unfortunately we do not do any color blending or matching.These are primary colors that can be blended together to achieve secondary and tertiary colors. Epoxy Fiberglass Resin BLUE GEL COAT MEDIUM SET 1.5 Gal Epoxy Resin GEL COAT YELLOW MEDIUM SET 1.5 Gal Epoxy Fiberglass Resin RED Gel Coat MEDIUM SET 1.5 Gal Epoxy Fiberglass Resin WHITE GEL COAT MAX GPE 1.5 Gal MAX GPE A/B MEDIUM SET is a two-component epoxy based resin system designed to provide a broad range of mechanical and physical properties that is suitable for almost all types of epoxy resin applications. It can be utilized as a structural adhesive demonstrating excellent adhesion to wide selection of substrates, chemical resistant or protective coating, impregnating and laminating for composite applications, potting applications for electronics and as a casting resin for large and small applications. MAX GPE A/B MEDIUM SET is mixed two parts Resin to one part Curing Agent by weight or by volume (2:1). The mixed consistency is very low in viscosity, clear and easily poured or applied in to place resulting in bubble free castings. MAX GPE A/B MEDIUM SET has a 60 minutes gel time that allows adequate working time for casting, coating, bonding and potting or encapsulating applications. MAX GPE A/B MEDIUM SET performs well as an adhesive for metals, alloys, plastic, wood, stones products, fiberglass, carbon fiber composites and concrete and other substrates that require high tensile shear strength properties. Higher adhesion performance can be achieved after a post cure cycle of 1 hour at 120oC. MAX GPE A/B MEDIUM SET coating properties exhibits very high gloss, good color stability, high surface and excellent chemical resistance. Optimized amounts UV inhibitors, anti-oxidants and stabilizers are incorporated with the MAX GPE A/B MEDIUM SET to provide added outdoor durability. An aliphatic polyurethane coating should be applied to further improved resistance to UV degradation. MAX GPE A/B MEDIUM SET can be used as a protective or decorative coating for metals, alloys, plastic, wood, stones products, fiberglass, carbon fiber composites and concrete and other substrates Higher coating performance can be achieved after a post cure cycle of 1 hour at 120oC. MAX GPE A/B MEDIUM SET is an excellent choice for composite fabrication using fiberglass, carbon fiber, Aramid, and other hybrid fabrics. Its low viscosity allows fast fabric wet-out resulting in minimal void and laminant porosity. Cured composites fabricated with MAX GPE A/B MEDIUM SET exhibits exceptional mechanical properties such as impact resistance, compressive and tensile strength. Higher mechanical performance can be achieved after a post cure cycle of 1 hour at 120oC. As a casting resin and potting compound, MAX GPE A/B MEDIUM SET demonstrates good dimensional stability excellent electrical insulative performance and low coefficient of expansion and contraction. General mechanical properties are enhanced after a post cure cycle of 1 hour at 120oC. Prepare all needed tooling and materials before mixing the resin and curing agent together. Pour the desired amount of resin then the curing agent in a clean container and gently mix with a spatula or mixing blade until uniform blend is achieved. Scrape the sides and bottom of the container to insure a thorough mix. Pour or apply the resin directly unto the prepare surface and allow to cure for at least 24 to 36 hours. The mixed resin will set-up in less than 2 hours and can be handled in 3 hours. PLEASE VIEW THE FOLLOWING VIDEO PRESENTATION. ALTHOUGH THE FEATURED EPOXY RESIN SYSTEM IS DIFFERENT THAN MAX GPE A/B, THE GENERAL TECHNIQUE AND PROPER MIXING PROCEDURE IS APPLICABLE. USE THIS MIX TECHNIQUE TO ELIMINATE TACKY SPOTS, UNCURED SECTIONS AND POOR MECHNICAL PERFORMANCE THAT IS CAUSED BY POOR MIXING AND INCORPORATION OF THE RESIN AND CURING AGENT. 100 parts A to 50 parts B by weight or volume 2 Hours @ 25oC Plus 1 Hour @ 120oC (1) Cured 2 hours at 80oC plus 3 hours 125oC (please look at our rules and privacy policy) |

S.mills@machine--tools.com (Shelly Mills) for additional information. This email is used for forwarding to newsgroup user.