|

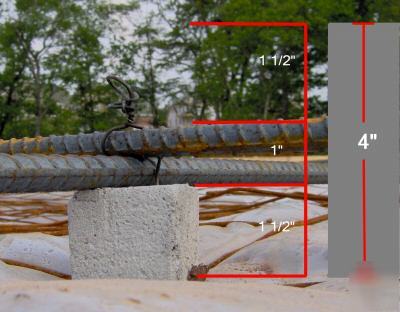

All Rebar Chairs Are Not The Same! All other support products have to be stepped around or they will bend, break, or puncture the poly or foam vapor barrier and that is just not possible when pouring concrete. So with other products, the rebar always gets mashed down under the concrete or your vapor barrier looks like swiss cheese, which does no good in either case. Ask anyone in the foundation repair industry, or any structural engineer where the reinforcing always ends up. They'll tell you. Unlike other rebar chairs, ReBlocs are 100% guaranteed not to: 1. Crush, sink, bend or displace even under the most extreme conditions arising from the pouring process. They have 4 square inches of "sand plate" or bearing surface to distribute the downward pressures (steel chairs provide 1/2 inch of surface)and no pointed legs to cut the vapor barrier. 2. Melt in the hot sun or break in the extreme cold. They are impervious to any weather and have an eternal shelf life. 3. Form an internal expansion joint from a non-bonding material, like plastic. ReBlocs partially absorb the cement slurry bonding the rebar chair to the slab. They actually get stronger, as the pour progresses, a very unique aspect. 4. Rust from electrolysis. This is a big problem that many don't know about. Uncoated steel chairs will create a chemical reaction that shows as orange stains in the finish years down the road. And there's nothing that can be done about it after it happens. 5. Built in tying wire means the rebar will be secured and not just laid on top of the support, where it can be kicked off. ReBlocs conform to all C.R.S.I. standards for bar supports as stated in Chapter 3 of the C.R.S.I.'s "Manual of Standard Practice". The 1 1/2" ReBloc measures 1 7/8" x 1 7/8" x 1 1/2" (+/- 1/8") which locates the rebar perfectly centered within a 4" typical slab. All ReBlocs feature a 16 gauge looped tie wire embedded in the block and will accomodate up to (3) #3 - 3/8", (3)#4 - 1/2" or (2) #5 - 5/8" rebar easily. The 1 1/2" ReBloc weigh's only 2.3oz's (+/- .15 oz) each and are designed to easily support the weight of the reinforcing and normal construction loads. We recommend you install a ReBloc under every rebar intersection for perfect results. If the rebar is spaced at 2' on center or less, then every other intersection is acceptable. But do not place more than 4' apart in any direction. This item is sold as 144 pieces with ground freight additional. Be sure to add me to your favorites list! To answer any building code questions: The Short Story. ReBlocs (a precast concrete cube) meet All Building Code regulations by classification from the Concrete Reinforcing Steel Institute (C.R.S.I.) as a class 1 bar support. The Long Story. Listen up, this may take a minute. The building codes do not specify which bar supports are approved or disapproved by referring to a specific ASTM or ANSI rating, because there are NO ASTM or ANSI ratings for rebar chairs. So, with no 3rd party ratings to hold everyone to, the building codes, as it often does, will differ to a code suggestion from the highest authority on the subject or the C.R.S.I., in this case. The C.R.S.I. issues a guide called The Manual of Standard Practices. In this guide, and more specifically chapter 3, it provides what is technically approved and rather than saying "yes" or "no" to certain products (since they themselves are not the inspectors) they issue a class rating for each type of product which thereby give a means by which anyone can specify that type of product without naming a specific product as what they want to be used. This rating is expressed as class 1, class 2, class 3 etc... A Class 1 product is the best support method and is what structural engineers always specify and is the only support class widely in use in California for example, where earthquake dangers make the structural integrity of foundation work very critical. As stated in the C.R.S.I. guide, chapter 3, section 3, precast concrete cubes qualify as a class 1 bar support. Class 2 are stainless steel supports. Class 3 are wire style supports (double rod chairs, steel high chairs) typically found in home centers. In this guide it is suggested that only class 3 or better supports should be used. This is why double rod rebar chairs are approved even though everyone knows they are highly ineffective. Are you getting the picture? By the way, there is no rating for anything makeshift or broken parts of other intended building materials. Why? Give me a break! This is why broken blocks and bricks are not allowed and it is not because of their basic components, portland cement, sand and aggregate which is indeed the basic components of a ReBloc. Again, broken parts of other intended materials are not allowed because they have no C.R.S.I. rating. In closing, Reblocs and other precast concrete cubes have been among the top rated products for rebar elevation since the rating system began. Don't let your fear of a building inspector who may not be familiar with this product keep you from using ReBlocs, he has no justification to reject your slab inspection just because you use ReBlocs. Rather, we find they like the product and ask for one so they can show others. (please look at our rules and privacy policy) |

Jimmie.Mayo@machine--tools.com (Jimmie Mayo) for additional information. This email is used for forwarding to newsgroup user.