|

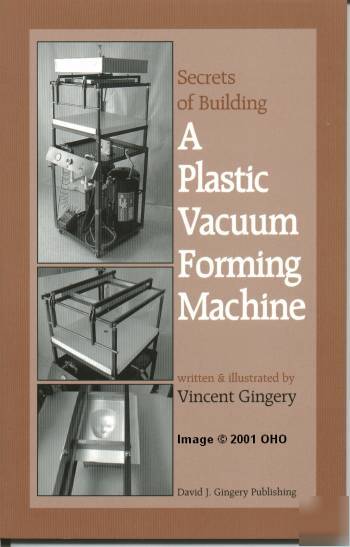

bounce, yer money order will get lost in the mail and yer dog won't come home. click on our "Contact Us" icon above for the quickest response to your questions. BUILD A VACUUM FORMING MACHINE PLASTIC PARTS BUILD A VACUUM FORMING MACHINE PLASTIC PARTS BUILD A VACUUM FORMING MACHINE PLASTIC PARTS BUILD A VACUUM FORMING MACHINE PLASTIC PARTS BUILD A VACUUM FORMING MACHINE PLASTIC PARTS BUILD A VACUUM FORMING MACHINE PLASTIC PARTS SECRETS OF BUILDING A PLASTIC VACUUM FORMING MACHINE Build Your Own Plastic Vacuum Forming Machine! Discover why vacuum forming is considered one of the most versatile of the plastic thermoforming processes. After covering basic plastic technology, you will learn how to make your own molds and use them to quickly form flat sheets of thermoplastic into intricate shapes with incredible accuracy. You will be able to fabricate unusual signs, plastic containers, decorative objects, model car and airplane bodies and more! After building and using your own vacuum forming machine, you will be capable of designing your own masterpiece projects! The secrets you need to build a large professional quality vacuum forming machine are here. Learn step-by-step how to design and build your own fully self-contained machine capable of molding thick sheet plastic with negative molds - a type of mold not often used in other machines. By building the platen attachment you can expand the capability of your machine to use positive molds as well. Simple angle iron construction and clever design make this a rewarding project to build. Best of all, you will save money. By investing a few dollars and a bit of labor, you'll end up with a machine, which if purchased, would cost far more! And when you start turning out products to sell at flea markets, craft shows, and hobby shops, you'll more than recover the small construction cost. Your machine will operate on a standard 20 amp 120 volt circuit, and it features an adjustable work surface to hold a variety of molds and sheet sizes. Your machine will use a dual vacuum source being either an air venturi pump or electric vacuum pump. And your professional quality forming machine will be on wheels making it easy to move when not in use. The secrets are here, Use them, add some imagination, and you will be amazed at what you'll be able to manufacture quickly and inexpensively! Soft cover 5 1 /2" X 8 1 /2" 106 pages. Visit my Marketworks Gallery! Power Tools for Power Sellers! Phone: (***) 744-4449 M-F 9:00 to 4:00 Pacific Standard Time This item has been seen by alt people! (please look at our rules and privacy policy) |

chahn@machine--tools.com (Chrystal Hahn) for additional information. This email is used for forwarding to newsgroup user.