|

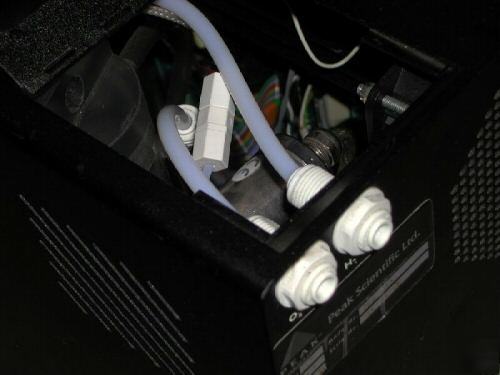

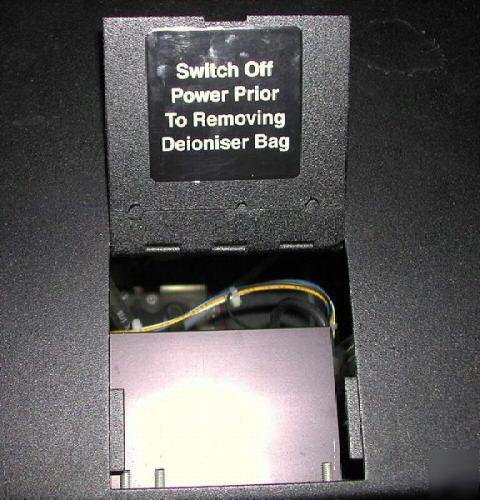

I looked up some info on the hydrogen generator. Here's a couple links I found: http:// /items/1137.htm http:// /new/gasgen-FAQs.htm http:// /new/gasgen_hydrogen.htm I have powered it up. The lights come on and I can hear the pump running but I don't have a source of deionized water to test it with. DO NOT USE TAP WATER IN THIS HYDROGEN GENERATOR! Use only deionized water. Tap water will damage the cell. The Hydrogen Generator works on the principle of disassociation of water through an ION Exchange Membrane to produce ultra-high purity gas. All other Generators use a combination of molecular sieves and filtration to produce different gases suited to your instruments. The Hydrogen Generators are completely silent. Nitrogen or Zero-Air Generators using house air supplies are also completely silent. Generators utilizing the built-in air compressors (part numbers noted with an ''A" suffix) are exceptionally quiet and feature a quiet purge (where necessary). Any noise comes from the cycling of the on-board air compressors, where applicable. What is the life expectancy of a Generator? All Generators have a life expectancy of 7-10 years. Keeping in mind that the ION Exchange Membranes from Hydrogen Generators currently in use have been running continuously for 12 years. The sieves used in the other Generators can be regenerated and will last indefinitely, providing the compressed air supply is always clean and dry. Is there any required maintenance? All Generators feature minimal maintenance requirements such as the periodic changing of filters. All Generators are built with lab safety in mind, and have safety features applicable to each gas. All Gas Generators are controlled by a mass flow controller, so it is not possible to overload the system at any time or produce low quality gases below specifications. Can outlet pressures be adjusted? Yes, on all Generators, either by using the Pressure Regulator provided or by using an additional Line Regulator at the instrument. What about installation procedures? Installation for each Generator is easy and only requires a connection to an electrical outlet, and dependent upon the Generator, either to your compressed air supply or to a supply of water. Does air need to be pre-filtered before entering the Generator? Yes, in all cases, the Generators are supplied with Pre-filters. However, we recommend that, if your house compressed air supply is extremely oily and dirty, that a further Pre-filter be put in the line to ensure absolute air quality. Can I hook up a back-up cylinder? Yes, this allows the system to be totally redundant in the event of a power failure or breakdown. It is suggested that the cylinder be hooked up using an Automatic Changeover Switch, so that it will kick in in the event of a loss of pressure at the Generator. What happens if purity drops below a certain level? Your first indication will be that you will notice a change in results produced at your instrument. The Generators should be checked, filters changed, sieves and membranes examined and changed if necessary. The Generators can be supplied with optional Oxygen Analyzers, if necessary. Peak is dedicated only to Gas Generators. Years of experience and knowledge give Peak the ability to satisfy your technical, commercial and personal requirements. The Generators are designed with your safety in mind. They feature automatic shut-down and visual/audible alarms to indicate high pressure or gas leaks both inside and outside the instrument. How is the oxygen separated from hydrogen in the Generator? The Generator features an ION Exchange Membrane in which hydrogen is produced. Oxygen is separated from hydrogen and is bubbled off with water into a holding chamber before it is automatically vented at the rear of the instrument. Do I need to use caustic solutions? No, the Peak Hydrogen Generator runs on deionized water. Maximum quantity of gas that can be stored in the Generator at any one time cannot exceed 400 ml at a maximum pressure of 100psi. No, the Generator is completely silent. How low a grade of water can I use? The Generator will accept deionized water @ <1µS/cm and will produce >99.9999% purity gas. DO NOT USE TAP WATER, tap water will damage the Cell. How do I load the Generator with water? The Generator features an automatic loading pump which, when attached to an external water supply, will pump water into the Generator, as required, allowing the user less maintenance. If the water supply runs low, an audible alarm will sound in the Generator to alert the user. Yes, simply hook up your water supply to the back of the instrument and the internal pump will fill the chamber inside the Generator, providing up to 350 liters of hydrogen from a single charge. What are my options for hooking up to an external water source? The Generator can be hooked up to a lab deionized water supply @ <1µS/cm or an external tank of water, which, if necessary, can be situated below the height of the Generator. How often does the reservoir need to be filled? A single charge of water in the Generator will supply up to 350 liters of hydrogen. This will depend on your usage of gas. What happens in the event of a power failure? How often does the desiccant need to be changed? Desiccant will turn from orange to green indicating that a change is necessary. This can take anywhere from 1 week to 6 weeks, depending on the size of the Generator and the gas consumed. Can I regenerate the desiccant? Yes, up to three times, at which point we would recommend the addition of a new desiccant to the drying cartridge. What is the Maintenance Schedule? Maintenance is limited to a change of the desiccant cartridge, as required. This can be anywhere from weekly to bi-monthly, depending upon the volume of gas consumed. For example, the HG200, running continuously for 24 hours per day, will only require a desiccant change once per month. Installation is easy – simply connect the Generator to your electrical supply and an external water source. The Generator will automatically pump water into the holding chamber, then, after a 4 minute “System Checkâ€, the Generator will automatically begin producing ultra-high purity gas. Pressure can be regulated at the rear of the instrument. The Peak Hydrogen Generators are the only Generators available with flows ranging from 200-600 cc/min. The ION Exchange does not require any caustic solution. Display indicates gas production and indicates leaks in the system or line. Safety devices indicate over-pressure and leaks. OK I bought some distilled water and tried it out. At first it wouldn't suck any water but once it started pumping water it quieted down. Then it started pumping water through the back two connections that say O2 Vent & H2 Vent (See picture 4 of 5). I turned it off before I got electrocuted. :) I nave no idea what connects there and I don't have a way to plug those vents or even if that would cause problems so I stopped there. I wish I had more knowledge about this equipment. I'd really like to see it run before I mail it away. If you have any more questions please let me know! And for whoever wins this thing I'd sure like to hear back when you get it running. Good luck! (please look at our rules and privacy policy) |

Cgordon@machine--tools.com (Crystal Gordon) for additional information. This email is used for forwarding to newsgroup user.