|

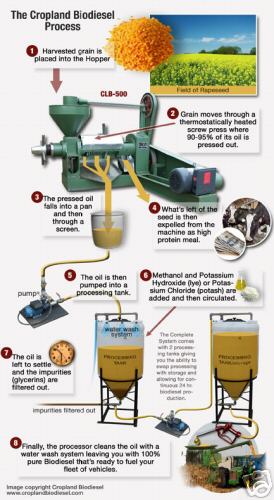

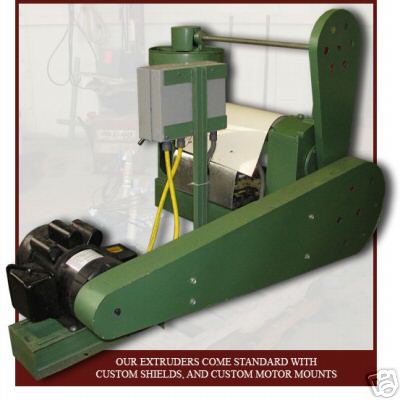

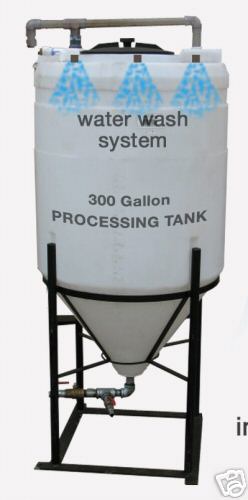

Seed Oil Extruder (with Heated Screw Press) We give you everything you need to get started. This system comes complete with Extruder (with Heated Press), 2 Processing Tanks (with custom built Water Wash System), Electric or Diesel Motor, 2 pumps, shields, belts, one extra set of Wear Parts, and Instructions. For more information visit us at: "In oil recovery by screw pressing, operating at elevated temperature enhances the oil yield, as reported by Bredeson (1983), Adeeko and Ajibola (1990) and Hamzat This quote comes from the Journal of Food and Engineering (2004) Development of a laboratory model screw press for peanut oil expression. by Ademola Oyinlola a,*, A. Ojo , L.O. Adekoya CLB-300 Extruder Specifications: (comes assembled) * Able to produce 200-300 gallons per day (2-3 tons p/day), 1500 gallons per week, 90,000 per year * Rotational speed of shaft: 30-40 rpm * 1 year Warranty (excluding Wear Parts) * Handle weight: 175-220 lbs/hour * Made of high tinsel strength steel * built right into the units casing * thermostatically controlled; gives accurate control of temperature * 3 heating elements surround the auger which allows you to heat the press allowing for higher yields of oil - 90 to 95% of the oil from the seed (as an example canola contains 30-35% oil, of that percentage 90 to 95% is expelled) * In the case of Soybeans, a temperature higher than 125°C (257° F) is needed to expel the highest yields of oil-with our heated press, this temp is easily reached * Allows you to quickly warm up your press by pre-heating the screw * Wear and tear of the heater and elements is also included in 1 year warranty * Comes with one set of wear parts * Dimensions: 50(l) x 20(w) x 40(h)in. * Made in China (assembled in the USA) "It is important that the screw press be heated so as to heat the meal as the latter is being pressed. It was found that enough friction (and therefore enough heat) could not be obtained from the oil-laden meal without the heating." This quote comes from the Journal of Food and Engineering (2004) Development of a laboratory model screw press for peanut oil expression. by Ademola Oyinlola a,*, A. Ojo , L.O. Adekoya Complete System also comes with: (some assembly required) * 2 - 115 gallon Processing Tanks that come with built in Water Wash System, allowing you to process and clean your oil and store it continuously 24/7 * Your choice of either a 5 HP Electric (AO Smith, 220 single phase, 60 cycle) or 7.75 HP Diesel Motor (R180, water-cooled, crank start w/ compression release (very easy to start) * Motor mount, shields, pullies and belts * 2 Processing Pumps; 110 volt, 1/2 HP, 500 gallons/hour, 60 cycle * In most cases it costs only $0.40-.70 cents per gallon to produce * Creates a byproduct of high protein livestock feed ($200 a ton) * Efficiently expels 90-95% of the percentage of oil within the seed (soybean contains 10-15% oil, of that percentage 90 to 95% is expelled) * USDA Loan for 25% toward the purchase of renewable energy systems such as Biodiesel Extruders This unit, as a Complete System, will weigh in at 950 lbs. The dimensions are: 50(l) x 20(w) x 40(h)in. The entire Complete System fits on a standard pallet. and Motor? We have many models to choose from Got everything but the Extruder or just want to add one onto your system? Compatible Oil-Seed Crops and Hot Pressing Optimal Temps: *These temperatures are recommended by the manufacturer for expelling the highest yields of oil. We will be putting up more information soon. In working with us you aren't just getting a press and then you're left on your own (unless you want it that way). We do not treat getting our systems up and running with a "just-plug-it-in-and-go" attitude. We will be there for you to help get your system up and running. We have more information (including our companies phone number and informational brochure) on our website located here: So, send us an email or give us a call! We look forward to doing business with you! (please look at our rules and privacy policy) |

n-dillon@machine--tools.com (Natasha Dillon) for additional information. This email is used for forwarding to newsgroup user.